In Denmark we all probably know the Hammel cured sausage from the refrigerated section in the supermarket. The Hammel cured sausage is produced at Delika's production unit in Haderslev, where the company's total production of quality sausages takes place. Here, Delika primarily manufactures grilled sausages and cured sausages, and in large quantities – namely more than 40 tons per week. The sausages are produced on three new VEMAG production lines.

Quality and ambitions in all aspects

Delika is one of Denmark's largest producers of cold cuts. The assortment covers the entire palette within cold cuts, smoked goods, cured sausages, and specialties.

Quality and taste count, regardless of the product, and this is reflected in the choice of raw materials, production methods, and machines.

At Delika, there is an ambition among the employees to produce food that they themselves would like to put on the table every day.

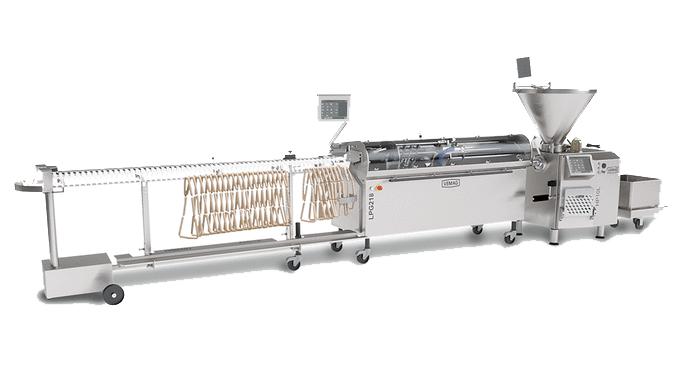

Three new VEMAG/Poly-clip lines in Haderslev

When the production lines in Haderslev were due for replacement, the choice naturally fell on Nemco. "We know Nemco well from before," says Ole Eriksen, who is the factory manager at Delika in Haderslev. "After the layout for the lines was in place, a test setup was set up at VEMAG. The finished line solutions, which ensure high process safety, include a Vemag LPG208 hanging line as well as two Vemag/Poly-clip lines."

Several of the operators at Delika have extensive experience in food production, and they were consulted before choosing the solution. They have also been to VEMAG in Germany for training and education.

Running with small staffing

The three production lines run with less staffing than was the case with the previous setup. Ole Eriksen tells us that Delika experiences great operational reliability and less waste with the new machines. "At Delika, we generally focus a lot on optimizing our line solutions, and with the new lines, we have future-proofed productivity," says Ole Eriksen.

Flexible solution

Service is a crucial factor, and we get better service at Nemco, Ole tells us. The agreement includes a maintenance contract, which creates security for us. In addition, it is always easy to get in touch with our contacts, and it is competent technicians and people from Nemco that we are in dialogue with. There is always a short response time, whether it is about service, ordering spare parts, or if we need additional purchases.

Overall, it is just a super fine collaboration we have with Nemco, concludes Ole.

"Service is a crucial factor, and we get better service at Nemco. It is always easy to get in touch with our contacts, and it is competent technicians and other employees from Nemco that we are in dialogue with."

Ole Eriksen

Factory Manager, Delika, Haderslev