Shrink bags/vacuum bags

We offer shrink bags, vacuum bags, cook-in bags and CVP bags of the highest quality with excellent packaging properties.

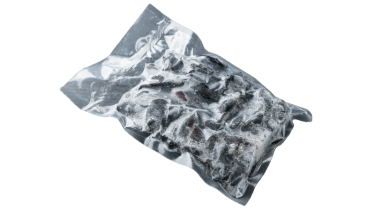

Shrink bags

Shrink bags

Our shrink bags are of high quality which provides efficient production and secures the product. The product is placed in the shrink bag, which is then sealed using fully or semi-automatic vacuum machines, then shrunk in the hot water tank or shrink tunnel. This packaging solution is ideal for products with bones, sausages, hams and cheese.

Features

Great shrinking properties (up to 50%)

Resistance to UV light

Excellent sealing properties

Extremely high strength, making boneguard unnecessary

Vacuum bags

Vacuum bags

Nemco's vacuum bags meet the requirements for packaging meat, fish, cheese, delicacies and groceries. The stable gas barrier ensures maximum product safety and aroma protection. The vacuum bags are available in many different sizes and thicknesses.

Features

Available in mono materials, which ensures the possibility of recycling

Available in various colours and sizes

Material thickness of 75my to 220my

Cook-in bags

Cook-in bags

Our cook-in bags are available in two different qualities: either made of OPA/ PP foil with a temperature resistance from -40° C to +121° C, or made of PA/PE with a temperature resistance from -40° C to +115° C. Both types guarantee a high oxygen barrier and excellent material strength. They are designed to hold tight in the cooking/autoclaving process.

Features

Can handle temperatures from -40° C to +121° C

No risk for delamination or leakage

No risk of flex rifts or streaks

Ideal for large kitchens

CVP bags

CVP bags

CVP bags are bags made of mixed materials (PE/PA/PE) which have a large volume that makes them especially suitable for the industrial handling of food. They are available in different thicknesses (60my-130my), and sizes.

Features

Available in various sizes

Ensures easy handling of the product in the production line

Available in different thicknesses (60my-130my)

Has large volume

Read more on our suppliers of shrink bags & vacuum bags

Explore our brochures

If you want to know more on this packaging solution, contact Michael!